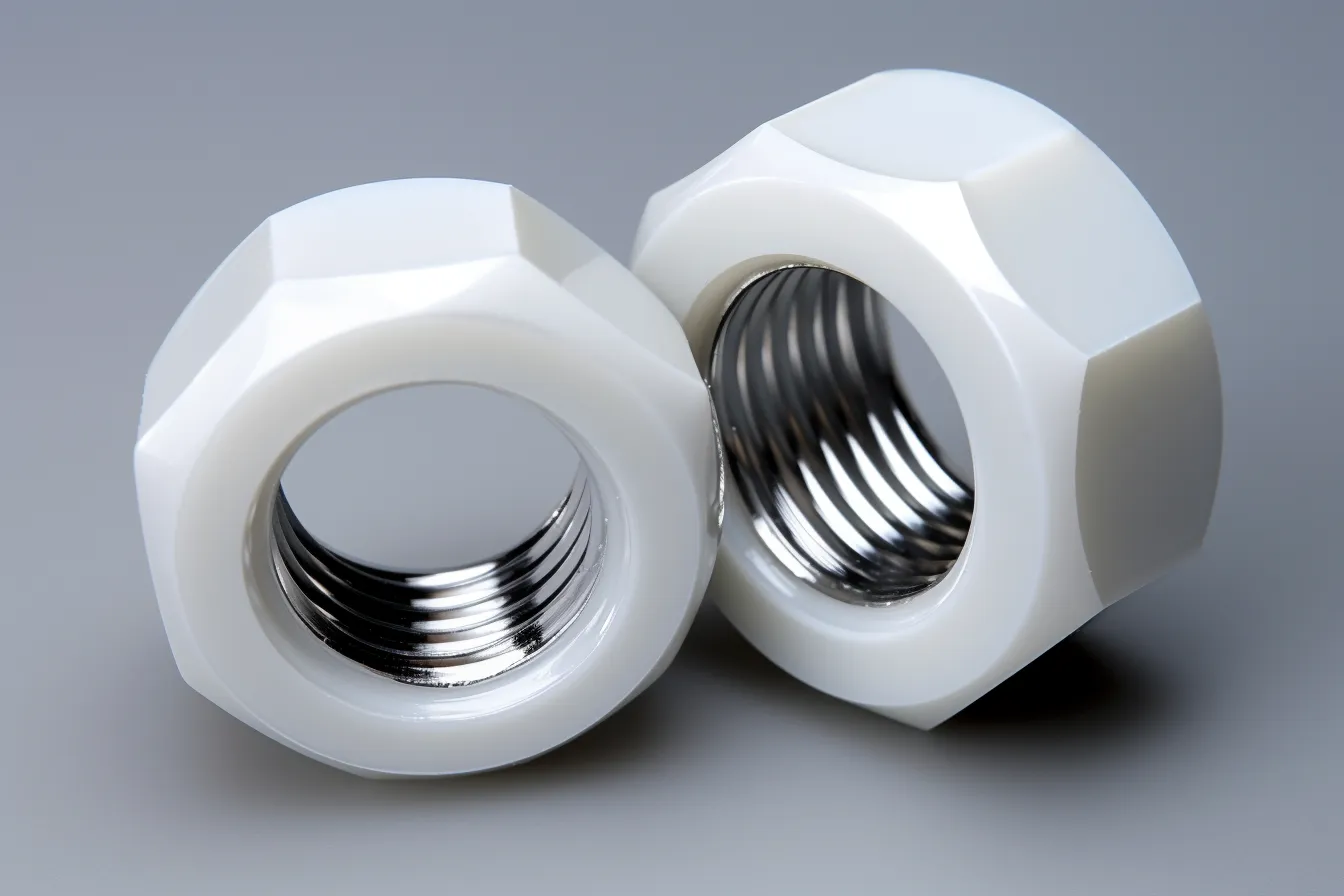

Locking nuts with nylon inserts are an invaluable tool for engineers seeking to create robust, vibration-resistant mechanical connections. This innovative nut design outperforms standard nuts in several key ways. Continue reading to discover the top 5 benefits of utilizing locking nuts with nylon inserts in your next project.

Introduction

Locking nuts containing a nylon insert offer superior performance compared to standard nuts in applications requiring high strength connections. The nylon insert creates greater friction against the bolt threads, effectively locking the nut in position. This prevents loosening from vibrations or dynamic loads. Locking nuts with nylon inserts deliver powerful locking action while protecting the bolt threads from damage. Let’s explore the top 5 reasons these nuts are a smart choice for critical mechanical joints.

5 Key Benefits of Locking Nuts Featuring Nylon Inserts

1. Enhanced Resistance to Loosening

The nylon insert creates greater friction between the nut and bolt threads compared to an all-metal locking nut. This added friction strongly resists loosening forces caused by vibrations, dynamic loads, or temperature changes. The nylon wedge-shaped insert compresses tightly between the bolt threads to maintain the preload tension. This self-locking action removes the need for secondary locking devices. You can be confident these nuts will hold tight through years of service.

2. Protection Against Bolt Thread Damage

The nylon insert separates the nut threads from the bolt threads. This cushioning effect greatly reduces galling, abrasion, and scuffing of the bolt threads during installation and use. By minimizing metal-on-metal contact, the nylon insert preserves the condition of the bolt threads. This extends the service life of the bolts. It also allows for easier disassembly when required.

3. Absorption of Vibrations and Impacts

The nylon insert has enough elasticity to absorb mechanical vibrations, shocks, and impacts. This damping effect minimizes the chance of loosening while also reducing wear and tear on mating parts. Locking nuts with nylon inserts are ideal for applications involving vibration, dynamic loads, or accidental impacts. The nylon insert acts as a shock absorber to protect the nut and bolt.

4. Self-Locking Ability

Once installed correctly, these nuts remain locked in position. Unlike plain nuts, vibration and shock won’t cause them to back off the bolt. The self-locking feature eliminates the need for additional locking elements such as cotter pins or safety wire. This simplifies installations while still ensuring robust, trouble-free operation.

5. Facilitates Disassembly

When it’s time for disassembly, locking nuts with nylon inserts can be removed without excessive force or damage to the bolts. The nylon insert allows you to disassemble the joint with hand tools. Damaged or stretched bolts can make servicing difficult. By protecting the bolt threads from harm, nylon-insert locking nuts permit easier maintenance and parts replacement when needed.

Applications Perfectly Suited for Locking Nuts

Locking nuts with nylon inserts shine in applications prone to vibration, shocks, or movement. Here are some examples where these nuts are utilized to prevent loosening failures:

- Industrial machinery – locking nuts maintain proper preload tension on machinery mounted using bolts.

- Vehicle suspensions – locking nuts keep suspension components tightly fastened despite road vibrations.

- Aircraft assemblies – used extensively to secure critical flight components.

- Motorsports – locking nuts withstand intense vibration in auto racing engines and drivetrains.

- Pipelines – used to secure pipe flanges, valves, and inline components.

- Stage equipment – secures lighting, speakers, and set pieces against vibration.

- Construction equipment – prevents loosening of bucket teeth, blades, and other high wear parts.

Insert Material Options

While nylon is the most common, inserts are also available in engineered plastics such as Delrin® acetal. These provide added chemical and temperature resistance while still cushioning and protecting the threads. Stainless steel and brass inserts offer high strength and corrosion resistance. Talk to your locking nut supplier about the best insert material for your specific application.

Choosing the Right Locking Nut Style

Locking nuts with nylon inserts are available in several styles:

- Lock nuts – contain offset threads that bind against the bolt threads. Best where space permits use of a full height nut.

- Low profile locknuts – similar to lock nuts but with minimal height for tight areas.

- Toplock nuts- washer flange on one end with nylon insert. Allow quick installation in tight spaces.

- Coupling nuts – contain two nylon inserts for connections taking axial and radial loads.

Discuss your design constraints with an engineer to select the optimal locking nut configuration. Proper selection helps ensure robust, lasting performance.

Why Choose Jmet Corp. for Your Locking Nut Needs?

Jmet Corp. provides top-quality locking nuts featuring high performance nylon inserts. We supply the exact locking nut style and size required for your application. Our extensive inventory includes inch and metric sizes to fit your bolts. We can also customize unique locking nut designs. Our expert staff delivers responsive customer service and quick turnaround times. Contact Jmet Corp. today to request your locking nut with nylon insert quote! Our locking nuts will keep your critical connections tight.

Conclusion

The next time you need robust, vibration-resistant joints, be sure to choose locking nuts containing nylon inserts. Compared to standard nuts, they deliver superior resistance to loosening, protect bolt threads, absorb shocks, allow easy disassembly, and provide self-locking performance. With the right locking nut design, you can create dependable, long-lasting mechanical connections. Connect with Jmet Corp. to get the ideal locking nuts tailored for your specific application needs. Our high-quality locking nuts with nylon inserts will get the job done right.