Carriage bolts are essential fasteners used in various construction, woodworking, and automotive applications. Their unique design, including a square neck and domed head, provides stability and prevents rotation once installed. When it comes to securing carriage bolts, a common question that arises is whether washers are necessary. In this article, we will explore the need for washers with carriage bolts, their benefits, and scenarios where their usage is recommended. So, let’s delve into the world of carriage bolts and washers to understand their interplay.

Understanding Carriage Bolts

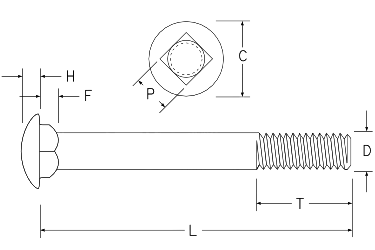

Before we dive into the need for washers, let’s take a moment to understand what carriage bolts are. Carriage bolts, also known as coach bolts, are sturdy fasteners designed with a round shank and a square neck underneath the domed head. This unique design allows them to be self-locking when tightened, preventing rotation during assembly. Carriage bolts are commonly used to secure wood to metal or wood to wood, offering a strong and reliable connection.

The Purpose of Washers

Washers, on the other hand, play a crucial role in the fastening process. They are thin, flat metal discs with a hole in the center. The primary purpose of washers is to distribute the load over a larger surface area, reducing the chances of fasteners pulling through the material. Additionally, washers can provide a smooth surface, preventing damage to the material being fastened. Different types of washers, such as flat washers, split lock washers, and fender washers, cater to specific fastening needs.

Do Carriage Bolts Need Washers?

Now, let’s address the question at hand: do carriage bolts need washers? The answer depends on several factors, including the specific application, the materials being fastened, and the desired level of stability. In some cases, using washers with carriage bolts is recommended to ensure proper load distribution and prevent damage. However, there are situations where washers may not be necessary, particularly when the materials being fastened are thick enough to prevent pull-through.

When to Use Washers with Carriage Bolts

While not always mandatory, there are scenarios where using washers with carriage bolts is beneficial. When fastening materials that are prone to splitting or damage, such as softwoods or thin metal sheets, washers act as a buffer between the bolt head and the material surface. This prevents the fastener from digging into the material and causing cracks or deformations. Additionally, washers can help distribute the load evenly, reducing stress concentration on specific areas.

Advantages of Using Washers

Using washers with carriage bolts offers several advantages. Firstly, washers enhance load distribution by providing a larger contact area. This helps prevent the fasteners from loosening over time, ensuring a more secure and long-lasting connection. Secondly, washers can protect the material from damage by providing a smooth surface for the carriage bolt head to bear against. This is particularly important when working with delicate or brittle materials that are prone to cracking or breaking under pressure.

Types of Washers Suitable for Carriage Bolts

When selecting washers to use with carriage bolts, it’s important to choose the right type for the specific application. The most commonly used washer types with carriage bolts are flat washers, split lock washers, and fender washers. Flat washers, as the name suggests, have a flat surface and are suitable for general-purpose applications. Split lock washers have a split design that provides additional tension and resistance to loosening. Fender washers, with their larger outer diameter, are often used when a wider load distribution is required.

Proper Washer Selection

To ensure optimal performance, it’s crucial to select the right washers for your carriage bolts. Consider factors such as material compatibility, size, and the demands of the application. For example, when working with outdoor projects or corrosive environments, stainless steel or galvanized washers offer better resistance to rust and corrosion. Additionally, ensure that the washer’s inner diameter matches the shank diameter of the carriage bolt, allowing for a proper fit.

Installation Process

Now that we understand the importance of using washers with carriage bolts, let’s briefly discuss the installation process. Begin by aligning the materials to be fastened and drilling appropriate holes. Place the washer over the shank of the carriage bolt, ensuring it sits flush against the material surface. Insert the bolt through the holes and tighten the nut securely. It’s crucial to avoid overtightening, as this can lead to material damage or compromised structural integrity.

Alternatives to Washers

While using washers with carriage bolts is generally recommended, there are alternative methods of fastening that may be suitable for certain applications. For instance, using threaded inserts or adding reinforcing plates can offer similar benefits in terms of load distribution and material protection. However, it’s important to evaluate the specific requirements of your project and consult with professionals to determine the most appropriate fastening method.

Common Mistakes to Avoid

To ensure the proper use of carriage bolts and washers, it’s essential to avoid common mistakes that can compromise the integrity of the connection. One common mistake is using washers that are too small or incompatible with the carriage bolts, resulting in uneven load distribution and potential fastener failure. Another mistake is overtightening the carriage bolts, which can lead to material deformation or even breakage. Always follow the manufacturer’s guidelines and exercise caution during the installation process.

Maintenance and Inspection

Once the carriage bolts with washers are installed, it’s important to prioritize regular maintenance and inspection. Over time, factors such as vibration, temperature changes, and environmental conditions can impact the stability of the connection. Periodically check for any signs of loosening, corrosion, or wear. Tighten any loose carriage bolts and replace damaged or corroded washers promptly to maintain the integrity of the fastening system.

Conclusion

In conclusion, the use of washers with carriage bolts depends on various factors, including the application, materials being fastened, and desired level of stability. While not always necessary, washers offer advantages such as load distribution and material protection. They are particularly beneficial when working with delicate or thin materials. When using washers with carriage bolts, select the appropriate type and size, ensuring compatibility with the application. Remember to follow proper installation techniques and conduct regular maintenance and inspections for long-lasting and reliable connections.

FAQs

1. Can I use any type of washer with carriage bolts?

While different types of washers can be used with carriage bolts, it’s important to choose the appropriate type for the specific application. Factors such as load distribution requirements, material compatibility, and washer size should be considered when selecting washers.

2. Are washers always necessary with carriage bolts?

Washers are not always necessary with carriage bolts. The need for washers depends on factors such as the materials being fastened and the desired level of stability. In some cases, when the materials are thick enough to prevent pull-through, washers may not be required.

3. Can I reuse washers when reinstalling carriage bolts?

It is generally not recommended to reuse washers when reinstalling carriage bolts. Over time, washers may experience wear or deformations that can compromise their effectiveness. It’s best to use new washers to ensure proper load distribution and material protection.

4. What should I do if I notice a loose carriage bolt after installation?

If you notice a loose carriage bolt after installation, it’s important to address it promptly. Check the tightness of the nut and tighten it securely. If the loosening persists, consider adding a lock washer or applying a thread-locking adhesive to prevent further loosening.

5. Are there any alternatives to using washers with carriage bolts?

Yes, there are alternatives to using washers with carriage bolts. Threaded inserts or reinforcing plates can provide similar benefits in terms of load distribution and material protection. However, the specific requirements of your project should be considered when determining the most suitable fastening method.