Finding the right tools for tightening and loosening hex nuts can be a challenge. With so many options on the market, how do you know which hex nut driver is best for your needs? Look no further! This comprehensive guide will walk you through everything you need to know about hex nut drivers, from basic features to top recommendations.

Introduction

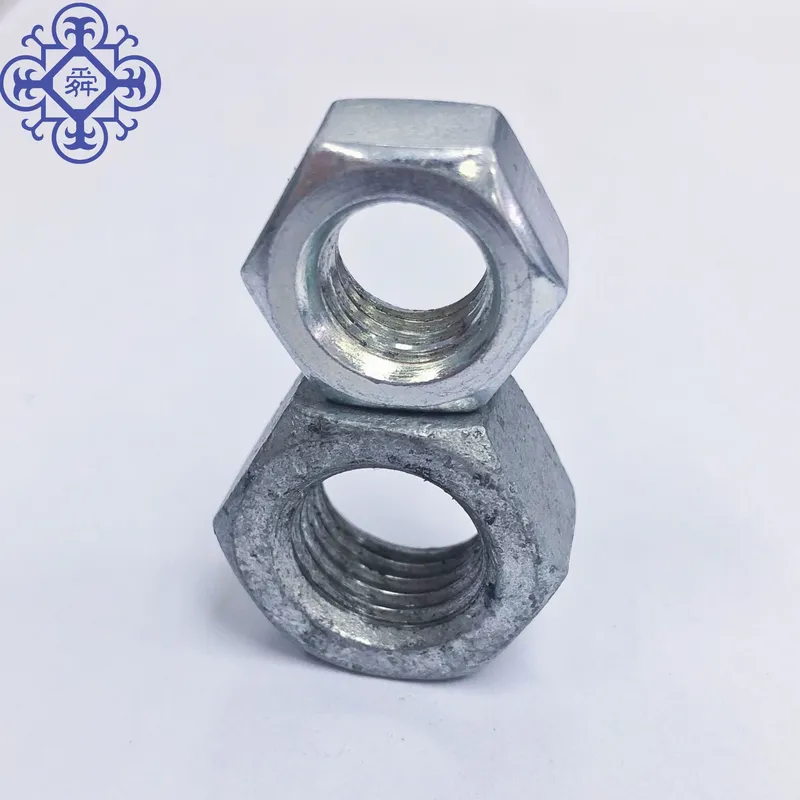

Hex nuts are six-sided nuts with an internal thread used to fasten bolts and screws. To properly install and remove hex nuts, you need a hex nut driver. These handy tools come with a hex-shaped bit or socket that grips and turns the nut.

Using the right hex nut driver allows you to generate sufficient torque for tightening applications without damaging or stripping the nut. It also prevents rounding off the corners on the nut, which can make removal extremely difficult.

This guide will cover:

- Hex Nut Driver Types and Features

- Hex Nut Sizes and Matching Drivers

- Manual vs. Power Hex Nut Drivers

- Torque Settings

- Top Hex Nut Driver Recommendations

- Pro Tips for Use and Care

Arm yourself with the knowledge to select, use, and maintain hex nut drivers for all your projects. Let’s get started!

Hex Nut Driver Types and Key Features

Hex nut drivers come in a variety of styles, sizes, and features. Some key considerations when selecting a hex nut driver include:

Bit or Socket Design

- Bit drivers have a hex-shaped bit that inserts into a socket handle or ratchet. These are used mainly for manual driving of nuts.

- Socket drivers have a hex socket built into the handle. These allow for use with ratchets or power drills.

Manual or Power Operation

- Manual drivers require the user to tighten or loosen nuts by hand. These include T-handle, L-handle, and ratcheting handle drivers.

- Power drivers connect to drills, impact drivers, or air tools to automate nut tightening and loosening.

Torque Limiting Features

- Some drivers have a clutch or slip mechanism to prevent overtightening and stripping of nuts. This is useful for delicate applications.

- Adjustable torque screwdrivers allow you to dial in a max torque setting.

Quick Release

- Drivers with a quick release allow for easy socket changes.

Ergonomic Handles

- Rubberized, anti-slip, or contoured handles help improve grip and reduce hand fatigue for frequent use.

Matching Hex Nut Driver Size to Hex Nut

Hex nut drivers and nuts are sized using the Standard Inch series based on the diameter of the nut. Common sizes include 1/4″, 5/16″, 3/8″, 7/16″, and 1/2″ hex nuts.

To properly tighten or loosen a hex nut, you’ll need a driver with the equivalent hex bit or socket size. Using an incorrectly sized driver can result in stripping, under-tightening, or damage.

Most sets include a range of driver sizes. Make sure the set you choose contains the sizes you’ll need for your particular hex nut applications.

Manual vs. Power Hex Nut Drivers

You’ll need to decide whether a manual or power driver is right for your tasks. Here’s an overview of the pros and cons of each:

Manual Hex Nut Drivers

Manual hex nut drivers require the user to physically turn the driver to tighten or loosen the nut. They allow for high precision in delicate applications but can be slow and laborious for driving large quantities of nuts.

Pros:

- Inexpensive

- No power source required

- Allow for “feel” while tightening

- Precise torque control

Cons:

- Slow for driving many nuts

- Can be labor intensive

- Limited torque/power

Power Hex Nut Drivers

Power drivers use electricity, pneumatics, or hydraulics to automate the tightening process. They are faster and make quick work of driving large numbers of nuts. However, they lack the touch and precision of manual drivers.

Pros:

- Fast for production applications

- Increased torque for stubborn nuts

- Reduce worker fatigue for frequent use

Cons:

- Less precision and touch

- Can overtighten if not careful

- Require power source

Consider your budget, power availability, precision needs, and workload to decide between manual and power hex nut drivers.

Proper Torque Settings

Applying the appropriate amount of torque when tightening hex nuts is crucial. Under-tightening can lead to loose connections and equipment failures. Over-tightening can damage threads and make removal incredibly difficult.

Recommended torque ranges vary based on the nut size, material, and application. Always consult the manufacturer’s specs for proper torque settings.

For generic guidance when manufacturer specs aren’t available:

- Use lower torque settings on small, delicate nuts

- Use higher torque settings for large, load-bearing nuts

- Tighten metal nuts more than nylon insert nuts

- Don’t exceed the yield strength of the nut’s material

Investing in a torque wrench or adjustable torque screwdriver allows you to accurately dial in and confirm proper torque. This helps avoid under or over-tightening issues.

Top Hex Nut Driver Recommendations

With so many hex nut driver options on the market, here are my top picks:

Best Manual Driver: TEKTON 3/8-Inch Drive 10-Piece Hex Nut Driver Set

- SAE sizes from 5/16” to 3/4″

- Tough chrome vanadium steel construction

- Cushioned rubber grip handles for comfort

- Includes extension for hard to reach nuts

Best Power Driver: Milwaukee Electric Hex Impact Driver

- High torque for stubborn nuts

- Variable speed trigger for control

- 1/4″ quick change hex chuck

- Protective boot for durability

Best Budget Driver Set: Neiko 01824A SAE Hex Nut Driver Set

- Heat treated S2 steel bits

- Sizes from 5/16” to 3/4″

- Affordable price point

- Durable plastic handles

Best Precision Driver: Channellock 810 Precison Nut Driver

- Laser heat-treated CR-v steel bit

- Slim shank reaches tight spots

- High visibility orange handle

- Torque limiting handle prevents overtightening

Pro Tips for Using and Caring for Hex Nut Drivers

Follow these professional tips to safely use and maintain your hex nut drivers:

- Avoid using adjustable wrenches or pliers on hex nuts whenever possible. They can round off nut corners.

- When tightening, use the appropriate driver size for maximum contact with the nut. Poor contact risks stripping.

- Start the nut by hand before using power drivers to avoid cross-threading.

- Keep drivers clean by regularly wiping off dirt, grease, and debris from the hex shafts.

- Lubricate stuck or rusted hex nut driver sockets to prevent rust buildup.

- Only use impact rated hex drivers with power tools to avoid shattering.

- Replace worn bits or damaged drivers to minimize risk of rounding off nuts.

Properly selecting and caring for your hex nut drivers helps ensure solid, trouble-free connections every time. Invest in quality tools and use the right driver for the job. Your nuts will thank you!

Conclusion

Securing hex nuts requires having the right hex nut driver for the task. Follow this guide to choose the ideal type, size, torque, and features for your particular applications. Investing in a quality driver set with both manual and power drivers enables you to tackle light duty or heavy nut driving jobs with ease.

Remember to use proper care and maintenance practices to keep your hex nut drivers performing optimally. And be sure to follow manufacturer recommended torque settings to prevent damage.

With the right knowledge and tools, you can drive hex nuts with confidence for any project. For help selecting customized hex nuts to meet your specifications, contact Jmet Corp. Our experts are ready to assist with your hex nut needs. Get in touch today to get started!