Carriage bolts are commonly used in various applications, including woodworking, construction, and furniture assembly. Properly tightening carriage bolts is crucial to ensure stability and prevent loosening over time. In this article, we will provide a step-by-step guide on how to tighten carriage bolts effectively. By following these instructions, you can ensure a secure and durable connection.

Steps to Tighten Carriage Bolts

- Gather the Necessary Tools

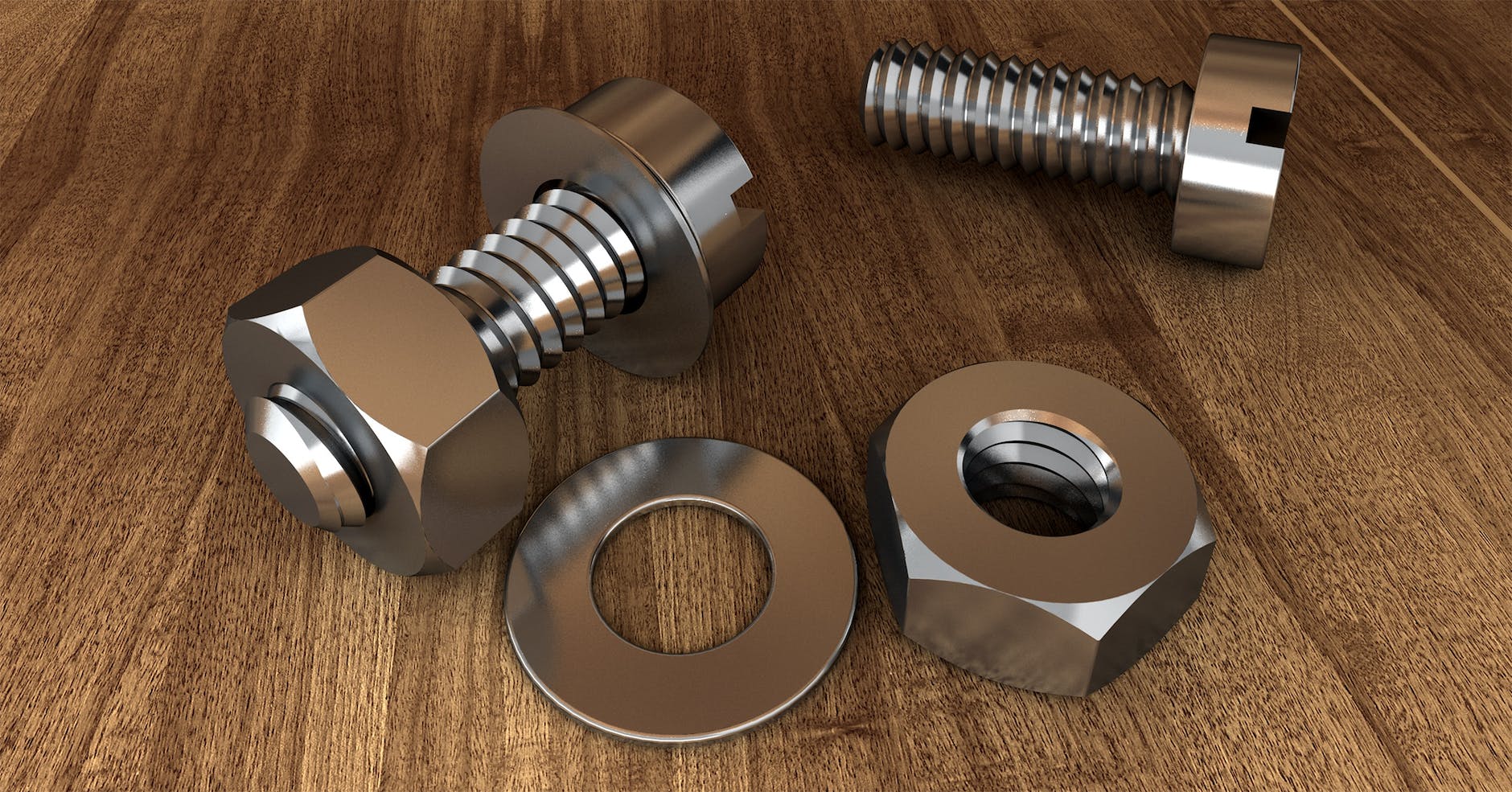

Before you begin, gather the tools required for the job. You will need a wrench (typically an adjustable or socket wrench) that fits the bolt’s head size, as well as a washer and nut that match the carriage bolt.

- Prepare the Bolt Hole

Ensure that the hole where the carriage bolt will be inserted is clean and free from any debris or obstructions. This will allow for smooth insertion and proper alignment.

- Insert the Carriage Bolt

Place the carriage bolt through the pre-drilled hole, ensuring that the rounded head is on the side where the bolt will be tightened. The square shoulder of the bolt should be on the opposite side, providing a secure grip within the material.

- Add the Washer and Nut

Slide a washer onto the threaded portion of the carriage bolt, followed by the nut. The washer helps distribute the load evenly and protects the surface from damage.

- Hand-Tighten the Nut

Begin by hand-tightening the nut onto the carriage bolt. This will ensure that the bolt is properly seated and aligned before applying additional force.

- Use a Wrench to Tighten

Once the nut is hand-tight, use a wrench to further tighten it. Gradually apply force in a clockwise direction, making sure to keep the bolt aligned with the hole. Avoid over-tightening, as it may cause damage or strip the threads.

- Check for Proper Tightness

After tightening the nut, check for proper tightness by ensuring that the bolt is secure and does not move or wobble. However, be cautious not to overtighten, as this can lead to material deformation or breakage.

- Inspect Regularly

Periodically inspect the carriage bolts to ensure they remain tight and secure. Over time, vibrations and other factors may cause the nut to loosen. If you notice any signs of loosening, retighten the nut promptly.

By following these steps, you can confidently tighten carriage bolts and achieve a secure and reliable connection.

- Consider Using Locking Mechanisms

In some applications where vibration or movement is a concern, you may want to consider using additional locking mechanisms to further secure the carriage bolts. One option is to use a lock washer, which has teeth that bite into the material and prevent the nut from loosening. Another option is to apply a thread-locking adhesive, such as Loctite, to the threads of the bolt. This adhesive creates a strong bond and prevents the nut from coming loose over time. These additional measures can provide an extra level of security and peace of mind.

- Seek Professional Help if Needed

If you encounter any difficulties or if you are unsure about tightening carriage bolts properly, it is always recommended to seek professional help. A professional can provide guidance, ensure the correct techniques are followed, and offer expert advice specific to your project’s requirements. It’s better to be safe and seek assistance rather than risking improper installation or compromising the integrity of the connection.

- Maintenance and Inspections

Once your carriage bolts are tightened and in place, it is essential to conduct regular maintenance and inspections. Check the bolts periodically to ensure they remain tight and secure. Factors such as temperature changes, vibrations, or external forces may cause the nuts to loosen over time. By inspecting and retightening the bolts as necessary, you can maintain the stability and reliability of the connection.

- Consider Environmental Factors

When using carriage bolts in outdoor or corrosive environments, it is crucial to consider the effects of moisture, humidity, and exposure to chemicals. These factors can accelerate corrosion and affect the integrity of the bolted connection. To mitigate the risk, choose carriage bolts made from corrosion-resistant materials such as stainless steel or coated bolts specifically designed for outdoor use. Applying an additional protective coating or sealant can also help prolong the lifespan of the bolts and maintain their performance under challenging conditions.

Data Table: Recommended Torque Specifications for Carriage Bolts

To ensure optimal tightening, refer to the following table for recommended torque specifications based on bolt size:

| Bolt Size (Diameter) | Recommended Torque (ft-lb) |

|---|---|

| 1/4″ | 5-8 |

| 5/16″ | 10-14 |

| 3/8″ | 16-20 |

| 1/2″ | 25-35 |

| 5/8″ | 45-55 |

| 3/4″ | 65-75 |

Please note that these torque values are general recommendations. Always refer to the manufacturer’s specifications for precise torque requirements.

Conclusion

Tightening carriage bolts correctly is essential for ensuring a secure and long-lasting connection. By following the step-by-step guide provided in this article and considering additional measures such as locking mechanisms, seeking professional help when needed, and conducting regular inspections, you can confidently tighten carriage bolts for various applications. Remember to refer to the recommended torque specifications and consider environmental factors to maintain the stability, reliability, and safety of your bolted connections.